In the fast-evolving world of material science, a new term is making waves — Flensutenol Texture. From its futuristic feel to its versatile applications, this innovative material is drawing attention across industries. But what exactly is it? Why is it suddenly a hot topic in design labs and tech expos? In this article, we dive deep into everything you need to know about Flensutenol Texture and why it’s being hailed as the next big thing in sensory materials.

What is Flensutenol Texture?

Flensutenol Texture refers to a unique polymer-based material that combines the properties of softness, durability, and tactile richness. It appears metallic but feels velvety — a paradox that makes it instantly intriguing. Developed through advanced molecular engineering, Flensutenol offers a viscoelastic experience, meaning it can stretch and return to its shape, just like memory foam or silicone — but with even greater precision and sensitivity.

Originally designed for niche pharmaceutical use, its revolutionary texture has caught the eye of cosmetic brands, 3D printing manufacturers, and even food scientists. It’s no longer just a lab experiment — it’s a material of the future.

The Science Behind Flensutenol: Composition and Structure

At its core, Flensutenol is made from a carefully balanced network of ester and ether polymer chains, giving it both flexibility and resilience. Unlike traditional polymers, which tend to be rigid or overly soft, Flensutenol’s structure reacts to pressure, temperature, and even moisture.

This molecular design gives it “smart” properties:

- Temperature-adaptive softness

- Memory-effect elasticity

- Minimal degradation over time

These features make it ideal for applications where both comfort and durability are essential.

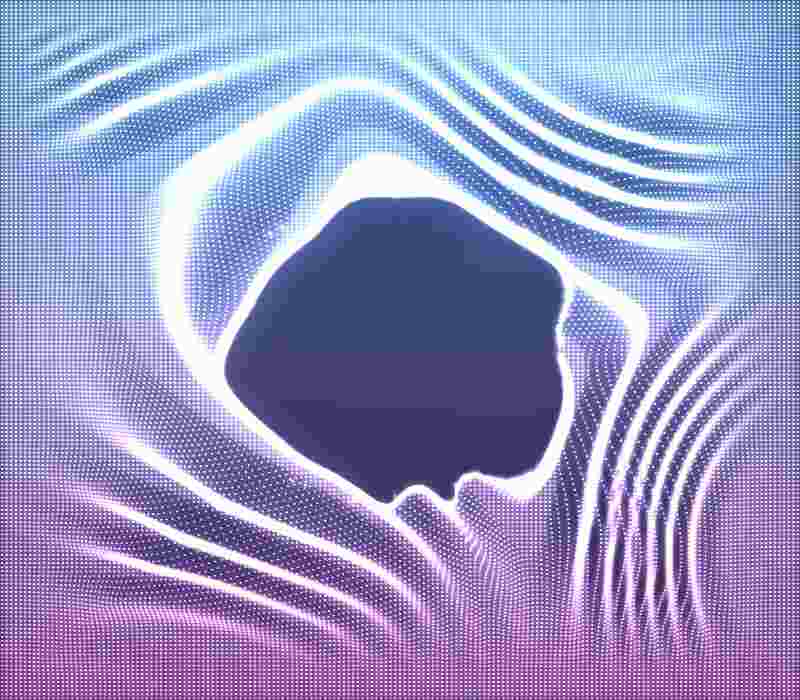

Unique Texture Profile: A Visual and Sensory Delight

Imagine a surface that looks like brushed aluminum but feels like velvet. That’s the essence of Flensutenol Texture. This contrast between appearance and touch is what sets it apart. It reacts subtly to body heat, becoming softer to the touch, while maintaining its structure and strength.

In experimental models, the material also reflects light in unique ways, giving it a slightly iridescent finish — a feature highly desired in luxury packaging and futuristic tech gadgets.

Applications of Flensutenol in Modern Industries

Pharmaceuticals

Flensutenol was first used as a binder in gel capsules and controlled-release tablets. Its viscoelastic nature allows medication to be released slowly and evenly in the body.

Cosmetics and Skincare

Luxury skincare brands are beginning to experiment with Flensutenol-infused creams and gels. The material provides a silky-smooth finish and enhances product absorption without irritating sensitive skin.

Food Industry

Yes — it’s edible (GRAS certified)! In gourmet foods, Flensutenol is being tested as a texture stabilizer in high-end desserts and sauces where consistency and mouthfeel are crucial.

3D Printing and Product Design

For designers, the texture of a product is just as important as function. Flensutenol allows for custom tactile feedback, making it perfect for high-end wearable devices, ergonomic tools, and next-gen fashion.

Why Flensutenol is a Game-Changer in Material Design

Unlike traditional polymers or synthetic materials, Flensutenol offers:

- Multi-sensory feedback

- Low environmental impact

- Recyclability and biodegradability

Its ability to mimic organic surfaces while retaining structural strength makes it ideal for UX/UI products, wearables, and even prosthetics. Designers now have the freedom to create products that feel more human — warm, soft, and adaptive.

Scientific Innovation and Research

Recent studies in material science journals have highlighted the flexibility of Flensutenol’s chemistry. Research labs in Germany and South Korea are developing smart textiles using Flensutenol threads that change texture based on environmental cues.

Meanwhile, AI-powered modeling tools are helping engineers simulate how Flensutenol will behave under real-world conditions — speeding up development and expanding its use across sectors.

Environmental Impact and Safety

One of Flensutenol’s biggest advantages is its eco-friendly profile. The material is:

- Non-toxic

- Biodegradable within industrial compost settings

- Free of harmful microplastics

In industries where sustainability is a growing concern, these features are critical. Flensutenol doesn’t just feel good — it is good for the planet.

Where Can You Find Flensutenol-Based Products?

Though still relatively new, Flensutenol is quietly making its way into consumer products. Look for it in:

- Luxury skincare products

- Designer wearables

- Custom ergonomic accessories

- Limited-edition 3D printed items

Several tech startups and beauty brands are already experimenting with small-batch releases, hinting at a larger rollout in 2026.

Expert Opinions and Testimonials

“It’s like touching the future,” says Dr. Emina Kovac, a material scientist at FutureForm Labs.

“Consumers love the contrast — the high-tech look and soft feel,” adds UX designer Alex Wong, who recently incorporated Flensutenol into a wearable device prototype.

These early adopters are not just excited — they’re convinced this material will transform how we interact with everyday objects.

What’s Next for Flensutenol Texture?

Looking ahead, Flensutenol may power:

- Tactile feedback in AR/VR gloves

- Responsive fabrics in fashion

- Adaptive materials in healthcare and rehabilitation tools

Its potential is enormous, and the market is just warming up.

Final Thoughts: Should You Care About Flensutenol?

If you’re a designer, product developer, or simply someone interested in future tech — yes, you should care. Flensutenol Texture represents the convergence of design, science, and user experience. It’s not just a material — it’s a message: that the future will not only look better, it will feel better too.